- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Sinae CNC Machina Visis fabrica, supplementum, Factory

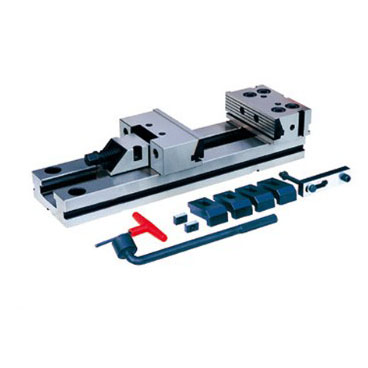

What is a CNC machine vise used for?

(1) Metalworking

Drilling: On a drill press or vertical milling machine, a vise can hold the workpiece firmly to ensure that the workpiece does not move during the drilling process.

Sawing, filing: A vise can hold the workpiece in place for sawing or filing operations.

Drilling, tapping, screwing: The vise's holding force can ensure that the workpiece remains stable during processing.

(2) Bench operations

Straightening, bending: A vise can hold the workpiece in place for straightening or bending operations.

Assembly and repair: A vise can hold the workpiece in place for assembly or repair operations.

(3) Woodworking

Vises are also very useful in woodworking projects, used to hold wood for shaping, carving, planing or sanding.

(4) Precision machining

Milling, grinding: A precision vise can ensure the stability and accuracy of the workpiece during machining.

Measuring and grinding: A precision vise can hold the workpiece in place for measuring or grinding operations.

How to use a vise safely?

(1) Installation and fixation

Firm installation: The vise must be firmly installed on the workbench to ensure its stability and safety.

Check the fixing screws: When using a swivel vise, the fixing screws must be tightened to prevent the vise from loosening during work.

(2) Inspection before use

Check the appearance: Before use, check whether the vise surface has cracks or damage. It is forbidden to use a vise that does not meet the regulations.

Check the mechanical parts: Check whether the lead screw and nut are loose, whether the rotating part is flexible, and ensure that all parts are in normal condition.

Jaw state: The jaws should be kept intact, and should be repaired in time when grinding to prevent the workpiece from slipping.

Qingdao Micro Precision Machinery Co. is ready to offer top-quality CNC machine vise to customers worldwide.

For 24 hours contact details as below:

Email: cyndee@wghydrauliccylinder.com

sales@wghydrauliccylinder.com

Mobile/whatsApp/Wechat: 0086-13793230712

- View as

Certain compositum modularis uises

ZZ-CCCXXXVI praecisione combinatione visorum sunt facta de alta qualitas Alloy Steel carburized, superficiem opus obdurat Hrc58-622, parallelismus 0.005mm / 100mm, 0.005m3 verticality 0.005m3. Removibilibus basi fixa faucibus mobilibus faucibus ieiunium tensis facile operationem. Late in machining centrum in praecisione apparatus instrumenta.

Lege plusMitte InquisitionemZQ83 unum et duplici actio uises

ZQ83 unum et duplex opus vises sunt de summus qualitas Alloy ferro carburized, operantes superficies obdurretur hrc58-62. Sunt late in machining centers, cnc milling velit, odiosis machinis, mentes et alia machina instrumenta.

Lege plusMitte InquisitionemZq80 vertical et horizontalis combination vises

ZQ80 vertical et horizontalis combination vises sunt in machining centers, cnc milling machinis, odiosis machinis, et molas et alia machina instrumenta.

Lege plusMitte InquisitionemQGG seriem praecisione tool uises

QGG Series Precising Tool vises ZZ-CCCXXX praecisione tool uises sunt pro praecisione mensura et inspectionem, praecisionem molere et electrica scintilla. Utrum sit libratum, rectum vel plana in opere potest efficaciter ponere altum praecisione.

Lege plusMitte InquisitionemCHM universalis vises

CHM universalis vises composita ex duabus partibus: et praecisione tool plana, nasum forcipe et turntable basi. Cum auxilio de lectus turntable, potest movere in CCCLX ° ° range in planum horizontalem et hastiludes XLV ° in verticali plano. Potest adhiberi ad praecisionem molere machinis, milling machinis etc. ad rectum, inclinata superficiem vel angularem superficiem machina et EXERCITATIO.

Lege plusMitte InquisitionemModel (XXVIII) DC altus praecisione Tool uises

Sinis Model (XXVIII) DC Precising Tool Vises

I: quod materia est facta de summus qualitas Alloy ferro et carburized ad operantes superficiem duritiam pervenire Hrc58-62. In summa firmum gerunt resistentia ensures quod accurate potest efficaciter praestatur in usu.

II: summus praecisione machina processus technology, pulvis-liberum conventum environment, in parallelismus inter duo lateribus et planum in dux rail et terram sit <0.002mm